Seating Barnes expander after 1st shot

#1

I am new to MLers and just got my first one a few weeks ago, an Optima . I tried the 300grain Barnes Expander and can get 3 shots within a few inches of each other with open sights at fifty yards(100 grains 777 pellets).

My question is by looking at the ramrod I can tell that every shot after the first one is seating about a full inch higher than the first shot. I have pressed with everything I got but I cant get them down any further. I have been running a wet patch between shots, maybe I need to run a wet and dry patch? Is it possible I am getting that much gunk from the 777 that the bullet cant go down any further? It doesnt seem to be effecting ignition or accuracy.Any thoughts from black powder vets?

My question is by looking at the ramrod I can tell that every shot after the first one is seating about a full inch higher than the first shot. I have pressed with everything I got but I cant get them down any further. I have been running a wet patch between shots, maybe I need to run a wet and dry patch? Is it possible I am getting that much gunk from the 777 that the bullet cant go down any further? It doesnt seem to be effecting ignition or accuracy.Any thoughts from black powder vets?

#2

Giant Nontypical

Join Date: Nov 2004

Posts: 5,425

Yep...Stop shooting when the bullet isn't firmly down on the powder...You will either blow the gun up or put a bulge in the barrel...

I don't like 777 because of the crud ring, prefer Goex or Pyrodex...You may have to go with 2 damp patches or even a brush between shots if you wan to stay with 777...You need to clean the barrel enough that the bullet will smoothly slide down all the way...You might also try a Crush Rib sabot as well...

I don't like 777 because of the crud ring, prefer Goex or Pyrodex...You may have to go with 2 damp patches or even a brush between shots if you wan to stay with 777...You need to clean the barrel enough that the bullet will smoothly slide down all the way...You might also try a Crush Rib sabot as well...

#3

First make sure your barrel is completely free of any oils before shooting. 90% Rubbing Alcohol works ok for this. Then pop a primer or 2.

Load and Shoot.

1 patch flipped once with 50/50 cheap Windex and rubbing alcohol mix (lightly damp) between shots. Follow up with a dry patch flipped once. Pop a primer if you got it too wet and it got in the breach plug.

Fire and repeat.

BTW a bullet not seated on the powder is no longer a bullet, its a barrel obstruction.

Load and Shoot.

1 patch flipped once with 50/50 cheap Windex and rubbing alcohol mix (lightly damp) between shots. Follow up with a dry patch flipped once. Pop a primer if you got it too wet and it got in the breach plug.

Fire and repeat.

BTW a bullet not seated on the powder is no longer a bullet, its a barrel obstruction.

#4

Northport buckslayr

You have been introduced to the famous Underclocked 'Crud Ring'.

Shooting T7 often creates this ring and stops the proper seating of a bullet as the heat of the explosion in the bore combines with other things that might be in your bore and creates a burnt residue ring.

Using a synthetic oil in the bore instead of an petroleum based oil and certainly an oil free of Teflon may help reduce the amount of the ring.

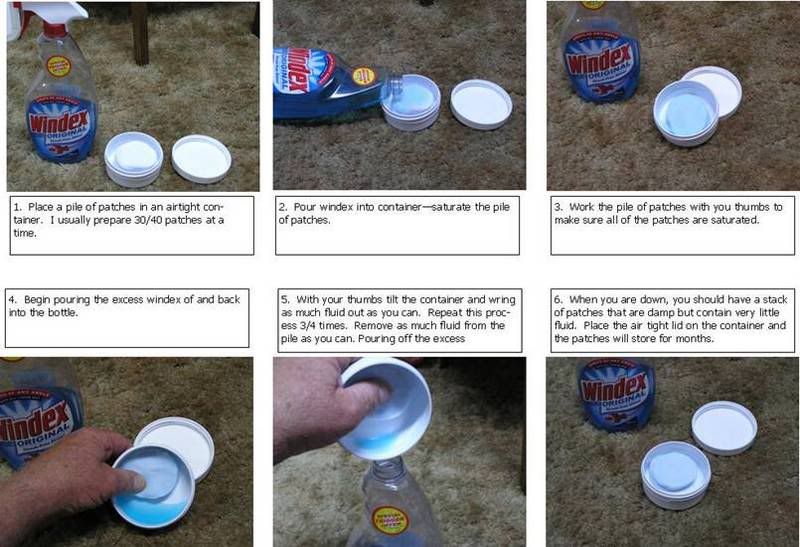

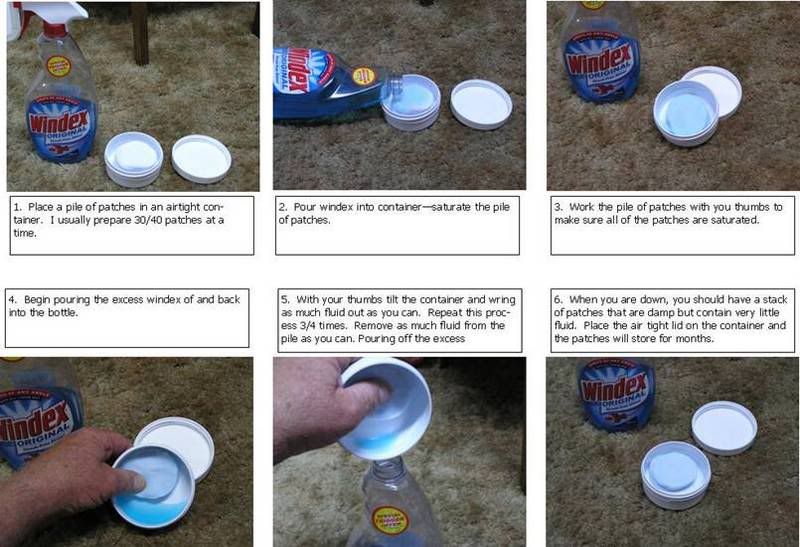

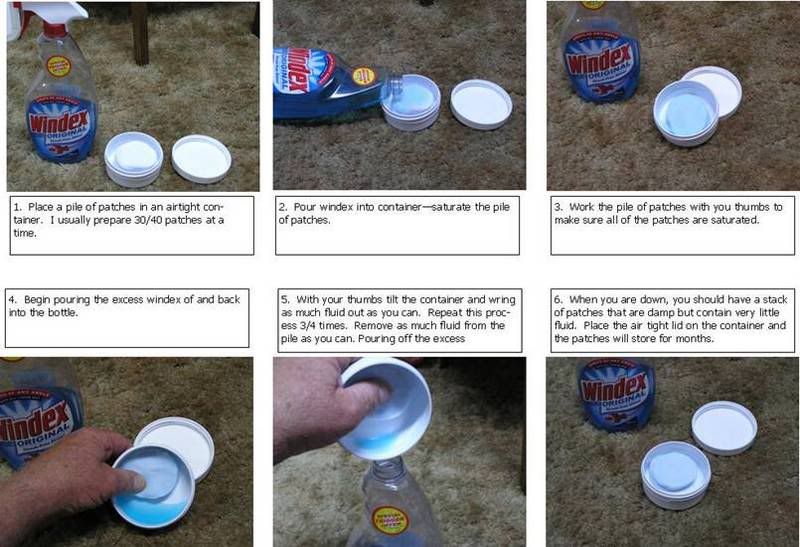

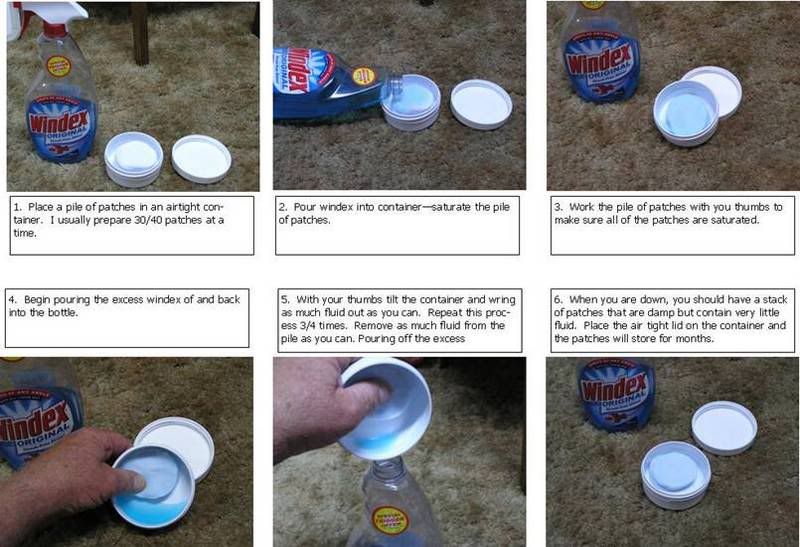

A simple way to get rid of the ring is to run a moist windex patch after each shot... I use the same over and over several times. If you make the patches with the correct amount of moisture you will not even have to run a dry patch... the ammonia in the Windex will dry and carry a certain amount of water with it...

Here is a picture that might help you pre-make some patches... Patching between shots also helps the barrel to cool before shooting the next shot.

The other thing you can do is shoot 'Black Gold' - BH 209 it has a bit of a learning curve but does not cause the fouling crud ring that T7 does.... I am still to cheap so I keep shooting T7.

You have been introduced to the famous Underclocked 'Crud Ring'.

Shooting T7 often creates this ring and stops the proper seating of a bullet as the heat of the explosion in the bore combines with other things that might be in your bore and creates a burnt residue ring.

Using a synthetic oil in the bore instead of an petroleum based oil and certainly an oil free of Teflon may help reduce the amount of the ring.

A simple way to get rid of the ring is to run a moist windex patch after each shot... I use the same over and over several times. If you make the patches with the correct amount of moisture you will not even have to run a dry patch... the ammonia in the Windex will dry and carry a certain amount of water with it...

Here is a picture that might help you pre-make some patches... Patching between shots also helps the barrel to cool before shooting the next shot.

The other thing you can do is shoot 'Black Gold' - BH 209 it has a bit of a learning curve but does not cause the fouling crud ring that T7 does.... I am still to cheap so I keep shooting T7.

Last edited by sabotloader; 02-07-2011 at 06:59 PM.

#5

Nontypical Buck

Join Date: Dec 2009

Location: Yucca Valley,Ca

Posts: 2,496

Yep...Stop shooting when the bullet isn't firmly down on the powder...You will either blow the gun up or put a bulge in the barrel...

I don't like 777 because of the crud ring, prefer Goex or Pyrodex...You may have to go with 2 damp patches or even a brush between shots if you wan to stay with 777...You need to clean the barrel enough that the bullet will smoothly slide down all the way...You might also try a Crush Rib sabot as well...

I don't like 777 because of the crud ring, prefer Goex or Pyrodex...You may have to go with 2 damp patches or even a brush between shots if you wan to stay with 777...You need to clean the barrel enough that the bullet will smoothly slide down all the way...You might also try a Crush Rib sabot as well...

#6

Nontypical Buck

Join Date: Dec 2009

Location: Yucca Valley,Ca

Posts: 2,496

Northport buckslayr

You have been introduced to the famous Underclocked 'Crud Ring'.

Shooting T7 often creates this ring and stops the proper seating of a bullet as the heat of the explosion in the bore combines with other things that might be in your bore and creates a burnt residue ring.

Using a synthetic oil in the bore instead of an petroleum based oil and certainly an oil free of Teflon may help reduce the amount of the ring.

A simple way to get rid of the ring is to run a moist windex patch after each shot... I use the same over and over several times. If you make the patches with the correct amount of moisture you will not even have to run a dry patch... the ammonia in the Windex will dry and carry a certain amount of water with it...

Here is a picture that might help you pre-make some patches... Patching between shots also helps the barrel to cool before shooting the next shot.

The other thing you can do is shoot 'Black Gold' - BH 209 it has a bit of a learning curve but does not cause the fouling crud ring that T7 does.... I am still to cheap so I keep shooting T7.

You have been introduced to the famous Underclocked 'Crud Ring'.

Shooting T7 often creates this ring and stops the proper seating of a bullet as the heat of the explosion in the bore combines with other things that might be in your bore and creates a burnt residue ring.

Using a synthetic oil in the bore instead of an petroleum based oil and certainly an oil free of Teflon may help reduce the amount of the ring.

A simple way to get rid of the ring is to run a moist windex patch after each shot... I use the same over and over several times. If you make the patches with the correct amount of moisture you will not even have to run a dry patch... the ammonia in the Windex will dry and carry a certain amount of water with it...

Here is a picture that might help you pre-make some patches... Patching between shots also helps the barrel to cool before shooting the next shot.

The other thing you can do is shoot 'Black Gold' - BH 209 it has a bit of a learning curve but does not cause the fouling crud ring that T7 does.... I am still to cheap so I keep shooting T7.

MY black gold will be here positively by the weekend!!! Ray

MY black gold will be here positively by the weekend!!! Ray

#7

I am new to MLers and just got my first one a few weeks ago, an Optima . I tried the 300grain Barnes Expander and can get 3 shots within a few inches of each other with open sights at fifty yards(100 grains 777 pellets).

My question is by looking at the ramrod I can tell that every shot after the first one is seating about a full inch higher than the first shot. I have pressed with everything I got but I cant get them down any further. I have been running a wet patch between shots, maybe I need to run a wet and dry patch? Is it possible I am getting that much gunk from the 777 that the bullet cant go down any further? It doesnt seem to be effecting ignition or accuracy.Any thoughts from black powder vets?

My question is by looking at the ramrod I can tell that every shot after the first one is seating about a full inch higher than the first shot. I have pressed with everything I got but I cant get them down any further. I have been running a wet patch between shots, maybe I need to run a wet and dry patch? Is it possible I am getting that much gunk from the 777 that the bullet cant go down any further? It doesnt seem to be effecting ignition or accuracy.Any thoughts from black powder vets?

Now pull that patch and flip it over and swab the bore all over again. It should swab easy. Now a dry patch and again, in short segments work that bore over. I like to use two dry patches. They will be the next wet patch for me. You want that bore clean.

Also another problem that you might be facing is the quality of the ramrod that comes with the rifle. Get a good stiff range rod. And when you load it, put a witness mark on it when the rifle is loaded. By witness mark, I take a piece of masking tape and wrap it around the ramrod level to the muzzle of the barrel. The next time you load, you should reach that same mark.

Try swabbing better, and get a range rod. It will save on your rifle rod.

#8

Fork Horn

Join Date: Apr 2005

Location: Dark Side of the Moon

Posts: 406

Welcome!!!! There is more great advice on here then you will ever have a chance to read. I had the same problem with T7 pellets. I took Cayugad's advice and marked the ramrod so I knew the bullet was seated properly. The only way I was able to load follow up shots and continue to seat the bullet to the same depth was to run a couple strokes down the barrel with a brass cleaning jag followed by 2 wet and 2 dry. Most people complain about the time it takes, but hopefully it is one shot kill anyways.

This became less of a problem for me as I always completely clean the rifle, fire 2 - 3 primers then run a dry patch down the barrel a couple times. I will then load up and go hunting. I want that first shot to be as consistent and as accurate as possible each and every time. I am not that concerned about punching holes in paper.

This became less of a problem for me as I always completely clean the rifle, fire 2 - 3 primers then run a dry patch down the barrel a couple times. I will then load up and go hunting. I want that first shot to be as consistent and as accurate as possible each and every time. I am not that concerned about punching holes in paper.

#9

Thanks for the advice all! I have just been swabbing with one spit patch, so my swabbing routine is about to get way more thourough. Is this an issue with everything but T7 (except BH209)? Do you get the same crud ring with pyrodex pellets, or white hots? Also would Hoppes Elite work as well as windex?

#10

Banned

Join Date: Dec 2010

Posts: 273

I have been following this advise since you or another fella told it about 5-7 years ago. And it has served me well. I swab every shot, and don't oil the barrel before hunting. And my cold bore POI stays the same day in and day out.