Accura Headspace Issues

#1

Nontypical Buck

Thread Starter

Join Date: Aug 2008

Location: Rapid City, South Dakota

Posts: 3,732

Actually, headspace issues are secondary to ignition issues in CVA rifles for users of BH209. Their breech plugs are designed to be used with pellets, and as such are not 100% reliable using BH. After suffering several hang fires, and one misfire in my Accura, i began the search for a fix.

At about the same time sabotloader posted about installing vent liner in a breech plug. This i did, and it cured the BH ignition issues. Before much more time went by, it dawned on me that a 5/8" x 18 grade 8 bolt would thread into the barrel of my Accura. It took me some doing, but eventually i made Accura breech plugs from them bolt. These plugs solved both the ignition issues, and the headspace issue.

The headspace of these plug is infinitely variable, and can be adjusted within 0.002" readily. At present the plug in my Accura was made to fit the STS primer, but can be changed to fit any longer primer, such as the CCI, W209, or the 209A. To fit a primer shorter than the STS, a new plug would have to be made from another bolt.

OH, OH!

Then when the issues of the Accura breech plug were dealt with, CVA came out with the V2 and the QRBP. However, because of previous experience, the cure for the issues came quickly.

First thing was to eliminate ignition issues before the first trip to the range, by installing a vent liner. Then the headspace issue was examined. STS primer in my V2 grow 0.020" when popped.

Fix 1..............The metric o-ring identified by Busta can be placed underneath the STS primer in my V2 when using the OEM plug, and makes a good seal, and helps keep the anvil of the primer in the cup.

Fix 2...............I went to our local ACE, and purchased a small sheet of 0.005" shim stock and punched out shims using what we used to call a leather punch. I made 4 of them and removed and replaced the firing pin bushing with these shim in place. This made for a cleaner burn, and the primer only grew a couple of thousandths or so.

Fix 3.................

This V2 breech plug is now sized to use STS primer in my rifle. The fix was forced on me because the plug suffered flame cutting in the primer pocket. My fault because i kept shooting it when the flame channel had closed down to 1/16". A tiny piece of debris kept the primer from seating and allowed the blow back which cut into the steel of the primer seat. Still, there are some that think this type of fix for excess headspace in these rifle is the best.

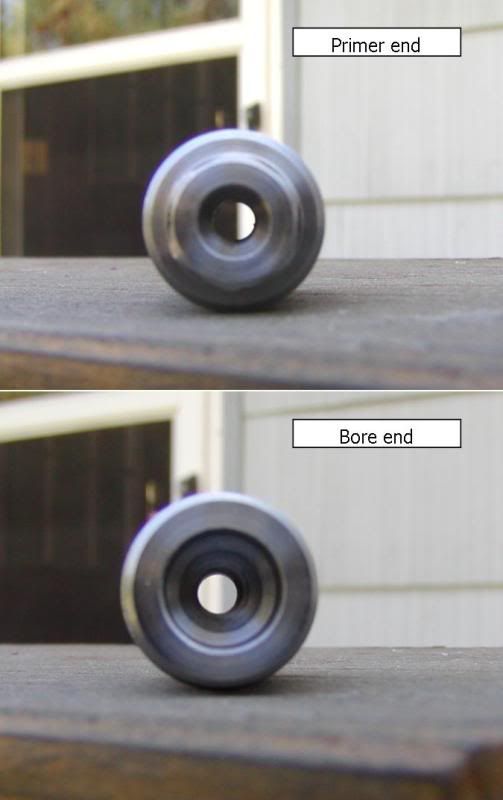

A fella from Montana contacted me about his Apex QRBP. He suffered excess blow by, and had no way to reduce headspace by unscrewing the firing pin bushing. He say the Apex is not made the same way as the V2, and that one cannot reduce headspace by unscrewing the firing pin bushing. He also wanted the plug to be reliable with BH. He mailed me his plug, and i fixed him up, and mailed it back to him. He called and said our plan worked. How we were able to arrive at a workable headspace long distance, i have no idea, unless it was because he lives a good clean life. His Apex plug...................

Next........................the Triumph.

At about the same time sabotloader posted about installing vent liner in a breech plug. This i did, and it cured the BH ignition issues. Before much more time went by, it dawned on me that a 5/8" x 18 grade 8 bolt would thread into the barrel of my Accura. It took me some doing, but eventually i made Accura breech plugs from them bolt. These plugs solved both the ignition issues, and the headspace issue.

The headspace of these plug is infinitely variable, and can be adjusted within 0.002" readily. At present the plug in my Accura was made to fit the STS primer, but can be changed to fit any longer primer, such as the CCI, W209, or the 209A. To fit a primer shorter than the STS, a new plug would have to be made from another bolt.

OH, OH!

Then when the issues of the Accura breech plug were dealt with, CVA came out with the V2 and the QRBP. However, because of previous experience, the cure for the issues came quickly.

First thing was to eliminate ignition issues before the first trip to the range, by installing a vent liner. Then the headspace issue was examined. STS primer in my V2 grow 0.020" when popped.

Fix 1..............The metric o-ring identified by Busta can be placed underneath the STS primer in my V2 when using the OEM plug, and makes a good seal, and helps keep the anvil of the primer in the cup.

Fix 2...............I went to our local ACE, and purchased a small sheet of 0.005" shim stock and punched out shims using what we used to call a leather punch. I made 4 of them and removed and replaced the firing pin bushing with these shim in place. This made for a cleaner burn, and the primer only grew a couple of thousandths or so.

Fix 3.................

This V2 breech plug is now sized to use STS primer in my rifle. The fix was forced on me because the plug suffered flame cutting in the primer pocket. My fault because i kept shooting it when the flame channel had closed down to 1/16". A tiny piece of debris kept the primer from seating and allowed the blow back which cut into the steel of the primer seat. Still, there are some that think this type of fix for excess headspace in these rifle is the best.

A fella from Montana contacted me about his Apex QRBP. He suffered excess blow by, and had no way to reduce headspace by unscrewing the firing pin bushing. He say the Apex is not made the same way as the V2, and that one cannot reduce headspace by unscrewing the firing pin bushing. He also wanted the plug to be reliable with BH. He mailed me his plug, and i fixed him up, and mailed it back to him. He called and said our plan worked. How we were able to arrive at a workable headspace long distance, i have no idea, unless it was because he lives a good clean life. His Apex plug...................

Next........................the Triumph.

#2

ronlaughlin

At the risk of going sideways again with MD, I think you have really worked yourself into a great project with fix #3. I believe it to be a lot more permanent and reliable.

Fix #2 would certainly be the next best option for the Accura/Apex senario.

It just seems to me that both of these options are more reliable than trusting an '0' ring over time. With both of your options metal on metal, all metal parts are supported by metal. You also reinforced my thought about metal movement on threads when you said that you 'tighted' the insert tight and machined it to fit.

Ron, another question your #2 fix brings to mind. Does the shim ring you build go between the base of the bushing and the frame or under the 'o' ring area? In my recent discussion with MD he feels the 'o' ring is used as the headspace device and indicates that the bottom of the firing pin bushing does not seat on the frame.

Makes me wish i had CVA just to look for myself. I am not sure my local sproting goods store would appreciate me taking apart one of their display guns to check a thought....

At the risk of going sideways again with MD, I think you have really worked yourself into a great project with fix #3. I believe it to be a lot more permanent and reliable.

Fix #2 would certainly be the next best option for the Accura/Apex senario.

It just seems to me that both of these options are more reliable than trusting an '0' ring over time. With both of your options metal on metal, all metal parts are supported by metal. You also reinforced my thought about metal movement on threads when you said that you 'tighted' the insert tight and machined it to fit.

Ron, another question your #2 fix brings to mind. Does the shim ring you build go between the base of the bushing and the frame or under the 'o' ring area? In my recent discussion with MD he feels the 'o' ring is used as the headspace device and indicates that the bottom of the firing pin bushing does not seat on the frame.

Makes me wish i had CVA just to look for myself. I am not sure my local sproting goods store would appreciate me taking apart one of their display guns to check a thought....

Last edited by sabotloader; 03-04-2011 at 08:33 AM.

#4

Nontypical Buck

Thread Starter

Join Date: Aug 2008

Location: Rapid City, South Dakota

Posts: 3,732

#6

I have opened all my Omega plugs with a #21 bit, just slightly greater than 5/32", the increase in flame channel diameter serves a couple of purposes, it allows the increase of volume the flash channel can handle and it increases the number of shots that can be shot before cleaning is necessary. With the addition of the reversed dome shaped Lehigh vent liner it further reduces the collection of blow back and carbon build up in the flash channel. The reversed dome sheds some of the blow back off to the sides of the liner and reduces the direct surface area that funnels blow back back into the breech plug.

When i was shooting a factory Omega/Encore breech plug I would try to remember to hand spin a 1/8" drill bit every 8-10 shots. This seemed to insured consistency from shot to shot.

In this picture you can see the increased size of the flame channel to allow better breating for the primer... This plug is drilled all the way out and tapped to allow installation of a hardened vent liner.

This picture shows the two type of vent liners that can be installed. I tried both the flat top and the dome and found the dome to provide a cleaner longer lasting plug over a range session.

In this picture you might be able to see the start of the carbon build up in a factory Knight plug.

But again if you are only an occasional shooter the factory Omega/Encore plug should serve you well as long as you do the maintenance on the channel...

Last edited by sabotloader; 03-04-2011 at 10:44 AM.

#7

I don't spend much time at the range. Just enough to sight in a scope/sights/loads. 99% of my shooting is hunting. Deer/elk/bear, and coyotes.

I do have an 1/8" drill that I use if I think it's being built up. Like you say. It doesn't take many shots for it to happen.

Just out of curiosity. I've been shooting real BP and T7 so far. So, i've just used the Remington Kleanbore primers.

As soon as the BH 209 shows up i'll be using the CCI 209m primers.

How do those two primers compare to clogging the flash channel?

I do have an 1/8" drill that I use if I think it's being built up. Like you say. It doesn't take many shots for it to happen.

Just out of curiosity. I've been shooting real BP and T7 so far. So, i've just used the Remington Kleanbore primers.

As soon as the BH 209 shows up i'll be using the CCI 209m primers.

How do those two primers compare to clogging the flash channel?

#8

Nontypical Buck

Join Date: Dec 2009

Location: Yucca Valley,Ca

Posts: 2,496

ronlaughlin

At the risk of going sideways again with MD, I think you have really worked yourself into a great project with fix #3. I believe it to be a lot more permanent and reliable.

Fix #2 would certainly be the next best option for the Accura/Apex senario.

It just seems to me that both of these options are more reliable than trusting an '0' ring over time. With both of your options metal on metal, all metal parts are supported by metal. You also reinforced my thought about metal movement on threads when you said that you 'tighted' the insert tight and machined it to fit.

Ron, another question your #2 fix brings to mind. Does the shim ring you build go between the base of the bushing and the frame or under the 'o' ring area? In my recent discussion with MD he feels the 'o' ring is used as the headspace device and indicates that the bottom of the firing pin bushing does not seat on the frame.

Makes me wish i had CVA just to look for myself. I am not sure my local sproting goods store would appreciate me taking apart one of their display guns to check a thought....

At the risk of going sideways again with MD, I think you have really worked yourself into a great project with fix #3. I believe it to be a lot more permanent and reliable.

Fix #2 would certainly be the next best option for the Accura/Apex senario.

It just seems to me that both of these options are more reliable than trusting an '0' ring over time. With both of your options metal on metal, all metal parts are supported by metal. You also reinforced my thought about metal movement on threads when you said that you 'tighted' the insert tight and machined it to fit.

Ron, another question your #2 fix brings to mind. Does the shim ring you build go between the base of the bushing and the frame or under the 'o' ring area? In my recent discussion with MD he feels the 'o' ring is used as the headspace device and indicates that the bottom of the firing pin bushing does not seat on the frame.

Makes me wish i had CVA just to look for myself. I am not sure my local sproting goods store would appreciate me taking apart one of their display guns to check a thought....

#9

Nontypical Buck

Thread Starter

Join Date: Aug 2008

Location: Rapid City, South Dakota

Posts: 3,732

ronlaughlin..........................Does the shim ring you build go between the base of the bushing and the frame or under the 'o' ring area? In my recent discussion with MD he feels the 'o' ring is used as the headspace device and indicates that the bottom of the firing pin bushing does not seat on the frame................................

I didn't change anything when i use my washer like shims. I just slipped them over the threads (4 of them 0.005" each) and tightened the bushing into place. I didn't study the situation closely when i had it apart. I was going to take it apart, and take a picture for you today, but i went and did some shooting this afternoon.

I guess what i see is the o-ring makes a seal between metal parts, and there is no metal to metal contact between the head of the bushing and the receiver, even when one uses the shims that i used. Hope this answers your question.

#10