Using super glue as a wood finish

#1

In another thread I showed a knife that I gave a super glue finish. I decided to show the steps I use. This is not to say that this is the only and proper way to use super glue as a finish. It's just the way I do it. Super glue is used on tropical woods that have oils that prevent most finishes from drying, curing or hardening but It can be used on any wood.

First of all, This is for small projects since it is not really cost effective for large projects. At the same time, there are those that use a super glue finish on pool cues, pens, bowls, chess pieces and a host of other projects.

I went out and bought a 4 pack of .07 Oz. tubes for $1.99. I bought the regular and not the gel but have heard of people using the gel with good results.

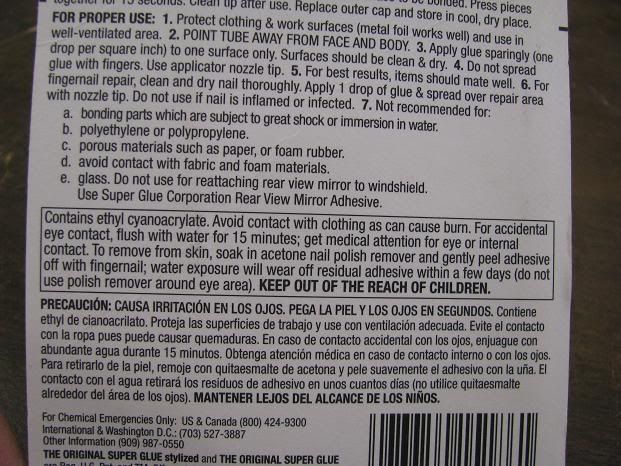

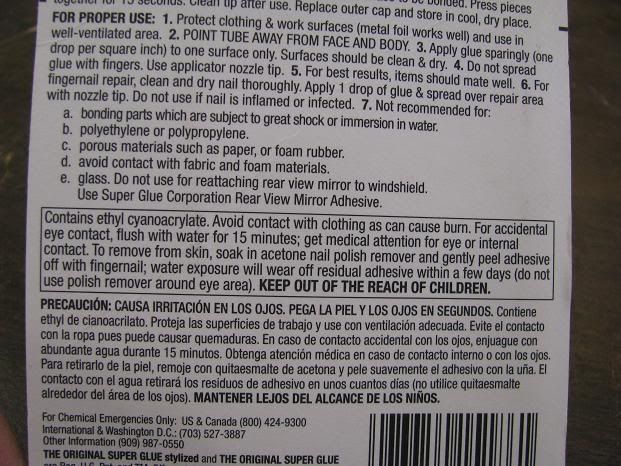

Always read the warnings and understand the risks. I have chosen to ignore rule number four. I found rule number five a bit odd. I do want good results but I fail to see why it matters how me and the missus spend our free time or if we are good at it.

This glue is stinky but larger containers that are more expensive can be bought in a low odor version.

I used a scrap piece of Bubinga right off the saw. I did not sand it at all. I did this to show that super glue is gap filling and fills in the pores of the wood. I poured a small drop on the wood.

And spread it around with this brush.

I just spread it out until the piece is covered and never stop moving. It stays liquid for a short while.

And then hardens with a little less gloss. You can see the rough saw lines on the wood. but after I build up of a few coats, it will smooth over the bumps. *** DO NOT blow on it to dry it faster.

After two coats, I use 400 grit sandpaper to smooth out the brush marks and then wipe it with a clean cloth to remove the white dust.

On the back side of the piece I applied the same number of coats except on the last one, I blew on it to dry it faster and you can see the results. The water vapor in your breath makes the glue cloudy or foggy and you cant un-do the damage. You will have to sand it all off and start over. The same goes for touching the wet glue with your finger. The moisture in your skin will also turn the glue white.

After a few coats, you also get a build up on the tip of your brush.

Nail polish remover (Acetone) will remove the hardened glue. I wet a paper towel and set my finger in it.

I will also use some of that same 400 grit to clean of any glue left behind. Now the brush is clean.

Once hardened, I use 400 grit and 0000 steel wool to smooth the finish.

Super glue leaves a hard, crystal clear and water proof protective coating of acrylic plastic on the wood.

It can be buffed to a high sheen.

Give it a try the next time you are working on a small wood project or if making fishing jig heads or turkey calls. Work outside or in an area with good ventilation.

First of all, This is for small projects since it is not really cost effective for large projects. At the same time, there are those that use a super glue finish on pool cues, pens, bowls, chess pieces and a host of other projects.

I went out and bought a 4 pack of .07 Oz. tubes for $1.99. I bought the regular and not the gel but have heard of people using the gel with good results.

Always read the warnings and understand the risks. I have chosen to ignore rule number four. I found rule number five a bit odd. I do want good results but I fail to see why it matters how me and the missus spend our free time or if we are good at it.

This glue is stinky but larger containers that are more expensive can be bought in a low odor version.

I used a scrap piece of Bubinga right off the saw. I did not sand it at all. I did this to show that super glue is gap filling and fills in the pores of the wood. I poured a small drop on the wood.

And spread it around with this brush.

I just spread it out until the piece is covered and never stop moving. It stays liquid for a short while.

And then hardens with a little less gloss. You can see the rough saw lines on the wood. but after I build up of a few coats, it will smooth over the bumps. *** DO NOT blow on it to dry it faster.

After two coats, I use 400 grit sandpaper to smooth out the brush marks and then wipe it with a clean cloth to remove the white dust.

On the back side of the piece I applied the same number of coats except on the last one, I blew on it to dry it faster and you can see the results. The water vapor in your breath makes the glue cloudy or foggy and you cant un-do the damage. You will have to sand it all off and start over. The same goes for touching the wet glue with your finger. The moisture in your skin will also turn the glue white.

After a few coats, you also get a build up on the tip of your brush.

Nail polish remover (Acetone) will remove the hardened glue. I wet a paper towel and set my finger in it.

I will also use some of that same 400 grit to clean of any glue left behind. Now the brush is clean.

Once hardened, I use 400 grit and 0000 steel wool to smooth the finish.

Super glue leaves a hard, crystal clear and water proof protective coating of acrylic plastic on the wood.

It can be buffed to a high sheen.

Give it a try the next time you are working on a small wood project or if making fishing jig heads or turkey calls. Work outside or in an area with good ventilation.

#4

But the rest of us call it "CA finish" or "acrylic coated" to hype it up a bit, instead of calling it "super glue".

Really popular in call making and pen turning to coat with CA (cyanoacrylate), for exactly the reason DIY mentioned, you can put a beautiful gloss on a call quite easily. A lot of call makers will argue that it's more brittle, and if you ding the CA finish, the chipping is much harder to repair (unsightly) than a ding in an unprotected wood surface, but CA's still very popular.

Really popular in call making and pen turning to coat with CA (cyanoacrylate), for exactly the reason DIY mentioned, you can put a beautiful gloss on a call quite easily. A lot of call makers will argue that it's more brittle, and if you ding the CA finish, the chipping is much harder to repair (unsightly) than a ding in an unprotected wood surface, but CA's still very popular.