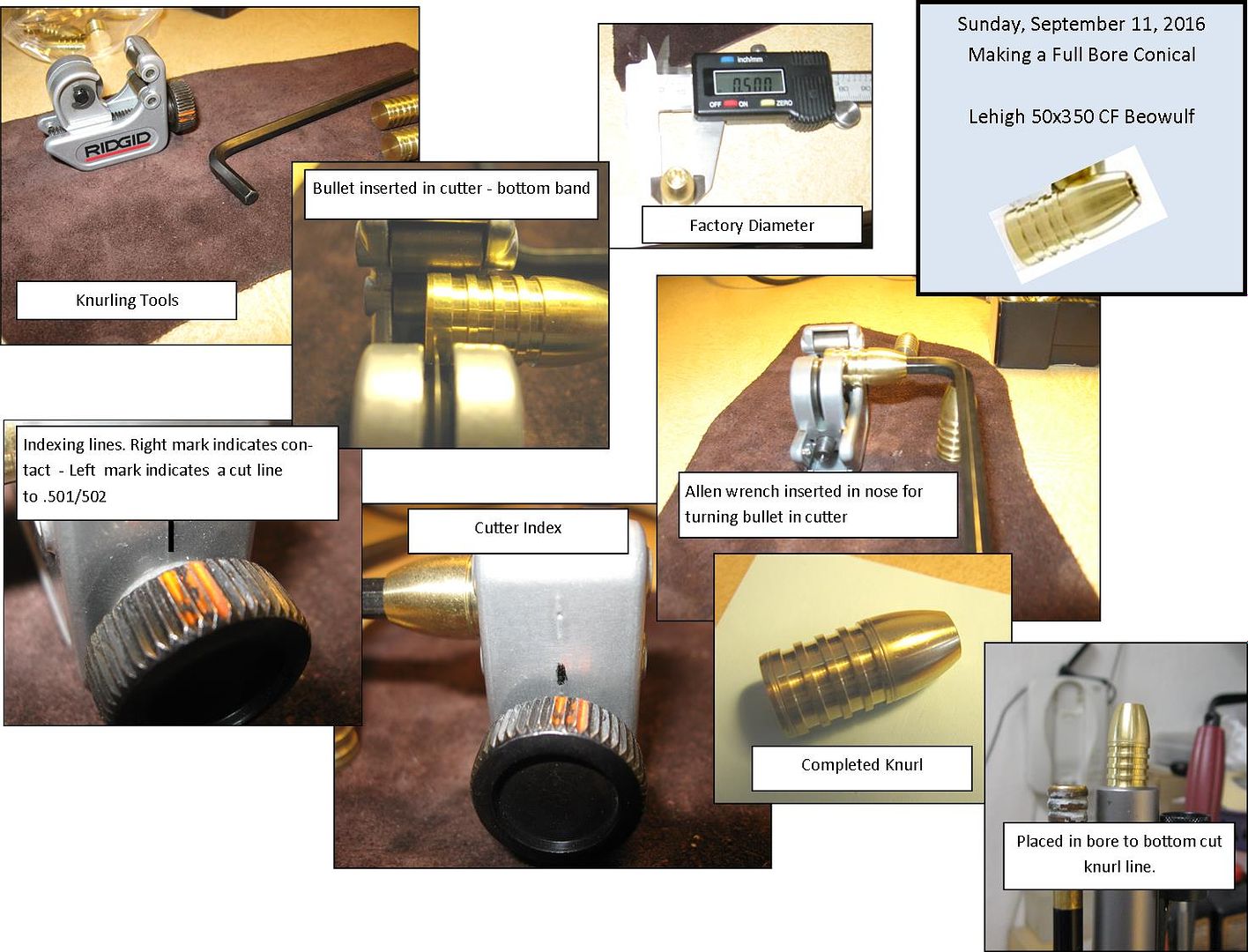

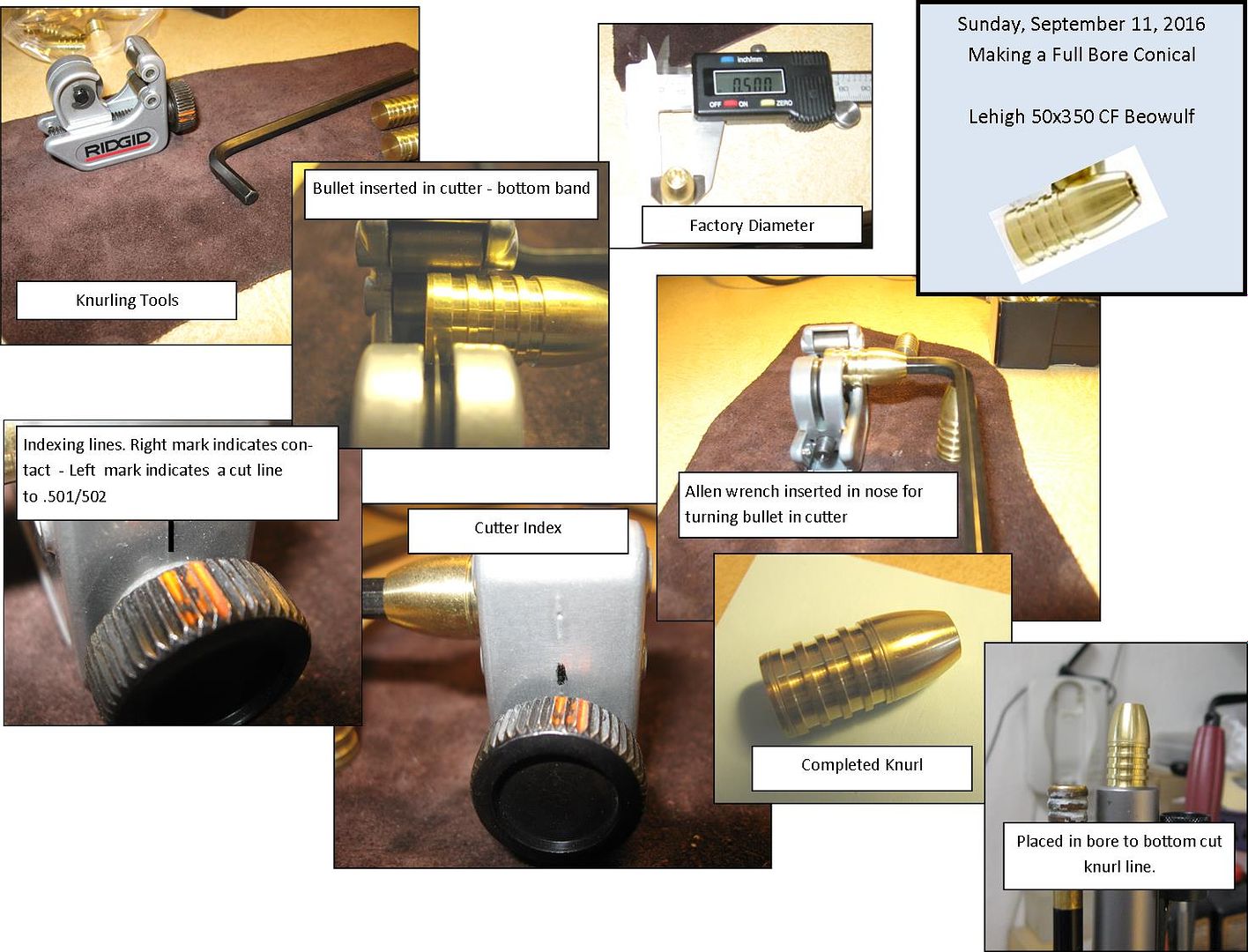

Making a full bore from a Lehigh 50x350 Beowulf bullet

#1

Had time on my hands this morning... football is starting and the dang Packers tried to give it away!!! but anyway thought I would try to show what I am doing with this particular bullet.

I picked up a box of Lehigh .500x350 CF bullets. These bullets were built for the 50 Beowulf. I am looking for an alternative to a lead or even copper bullet that I could use full bore. Naturally I can not use it here in Idaho during ML season but during the normal rifle season I could.

I am a fan of the Terminal Ballistics of the Lehigh bullet... + in a discussion with Lehigh Dave he suggested that there was such a thing as a 'bore riding bullet'. It does not have to fill the grooves to be accurate! I did do some reading on Lutz Moeller and his bore riding bullets. I was not convinced that an easy loading bullet with a gas check could be accurate - but today I am convinced that it can happen. The bullet just needs a grip on the lands for rotation.

I have been using the Lehigh/Knight .50x325 ML bullet for a couple of years working to make it effective. Some of these bullets 'factory sized' will fit in my bore with very little pressure - easy to push down with a gun rod (although a tight enough fit that they will not come off the powder). These have shot very accurately for me.

In an effort to reduce costs - I found the Lehigh 50x350 Beowulf. In my Knight Ulite - these bullets will slide slowly down the bore under their own weight. Another reason I like the Beowulf - the bullet is built for a centerfire - so the bullet is manufactured to much tighter specs - which makes each bullet almost identical in weight and diameter. This makes it much easier to get a consistent knurl.

My first attempts were to knurl them between to files which worked but it was not consistent. + brass is much more difficult to knurl than copper or lead. I needed a better way! Think I have found it - with some simple tools.

I know it is really hard to see the small cut knurling lines in the bullet. At the present time I am trying to do it with two cut lines - one near the base of the bullet and one at the top of the ogive.

The cut lines give me a bullet diameter of .501/.502 and works very well in my bore.

Hoping to get out to the farm early next week for velocity and accuracy checking of these newly knurled bullets...

I picked up a box of Lehigh .500x350 CF bullets. These bullets were built for the 50 Beowulf. I am looking for an alternative to a lead or even copper bullet that I could use full bore. Naturally I can not use it here in Idaho during ML season but during the normal rifle season I could.

I am a fan of the Terminal Ballistics of the Lehigh bullet... + in a discussion with Lehigh Dave he suggested that there was such a thing as a 'bore riding bullet'. It does not have to fill the grooves to be accurate! I did do some reading on Lutz Moeller and his bore riding bullets. I was not convinced that an easy loading bullet with a gas check could be accurate - but today I am convinced that it can happen. The bullet just needs a grip on the lands for rotation.

I have been using the Lehigh/Knight .50x325 ML bullet for a couple of years working to make it effective. Some of these bullets 'factory sized' will fit in my bore with very little pressure - easy to push down with a gun rod (although a tight enough fit that they will not come off the powder). These have shot very accurately for me.

In an effort to reduce costs - I found the Lehigh 50x350 Beowulf. In my Knight Ulite - these bullets will slide slowly down the bore under their own weight. Another reason I like the Beowulf - the bullet is built for a centerfire - so the bullet is manufactured to much tighter specs - which makes each bullet almost identical in weight and diameter. This makes it much easier to get a consistent knurl.

My first attempts were to knurl them between to files which worked but it was not consistent. + brass is much more difficult to knurl than copper or lead. I needed a better way! Think I have found it - with some simple tools.

I know it is really hard to see the small cut knurling lines in the bullet. At the present time I am trying to do it with two cut lines - one near the base of the bullet and one at the top of the ogive.

The cut lines give me a bullet diameter of .501/.502 and works very well in my bore.

Hoping to get out to the farm early next week for velocity and accuracy checking of these newly knurled bullets...