Adding ventliner to Omega plug

#1

Nontypical Buck

Thread Starter

Join Date: Jan 2008

Location:

Posts: 1,408

Awhile back there was some traffic about putting Savage-style ventliners in other plugs. I'm now becoming convinced that after close to a thousand rounds my Omega's plug is starting to go south. As a reminder, who has done this and how involved was it? I don't have access to much in the way of shop tools right now.

#2

Giant Nontypical

Join Date: Nov 2005

Posts: 6,585

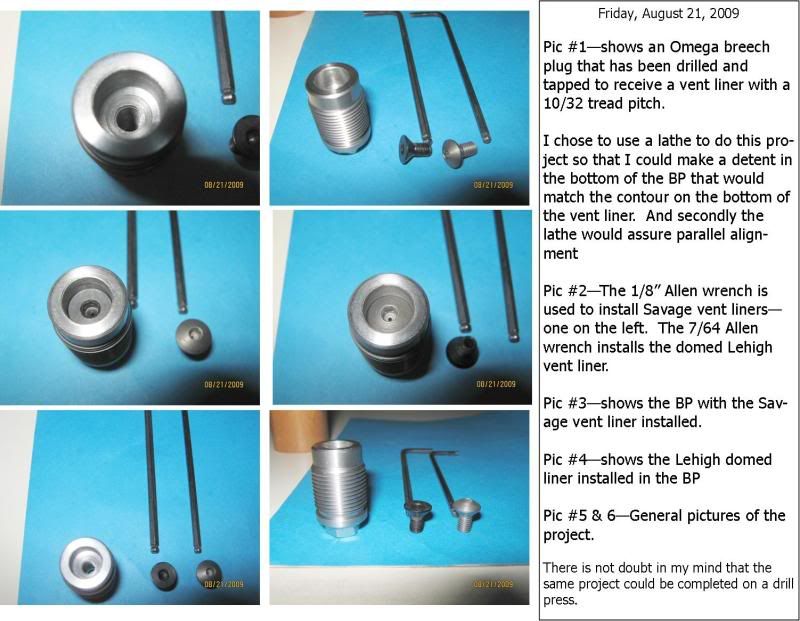

Sabotloader and myself have done it I have done 3 know and am delighted with the results. I now believe that the vent liners improve the consistency of the group or maybe it is the way we are installing them. I was working on the idea of making one and putting it in a couple years ago. Mike came up with the idea of drilling the hole the size needed [a #21 drill] all the way through and using the harder Lehigh vent liner [I had used a savage for the only one I had done. For some reason this makes a difference on how much carbon is deposited. The fancy BP for the Triumph and the Endeavor are expensive. and the vent liners run about 5 dollars a piece and it takes about 20 minutes to install the first one then if you ever need to [they are much harder and more flame cut resistant than the original BP] only a minute to change.

Mike used a lathe I used a drill press with a milling table. The procedure is easy I believe I could do it with a hand drill and a vise. Jut drill all the way through with a #21 drill and tap the muzzle end of the plug with a 10-32 tap. I only put 1.5 to 2 more threads than needed I count the threads on the vent liner and I use the drill press turned off and turned it by hand for the threading. [This makes sure every thing is strait with the drilled hole.] I set it up for strait by putting a drill that just fit in the drill press upside down then using that to position the milling table vise before I locked the plug down in the vise.

Hope this helps. Lee

Mike used a lathe I used a drill press with a milling table. The procedure is easy I believe I could do it with a hand drill and a vise. Jut drill all the way through with a #21 drill and tap the muzzle end of the plug with a 10-32 tap. I only put 1.5 to 2 more threads than needed I count the threads on the vent liner and I use the drill press turned off and turned it by hand for the threading. [This makes sure every thing is strait with the drilled hole.] I set it up for strait by putting a drill that just fit in the drill press upside down then using that to position the milling table vise before I locked the plug down in the vise.

Hope this helps. Lee

#3

spaniel

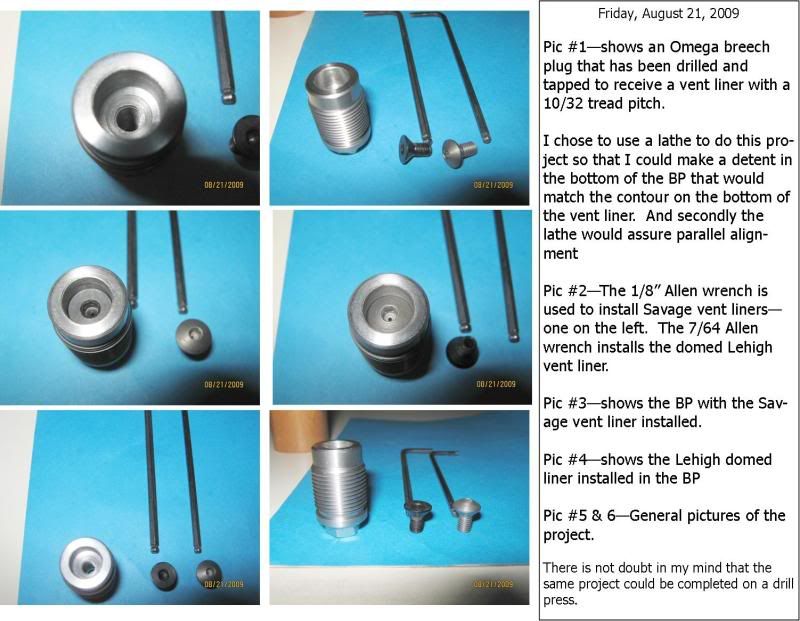

Both Lee and I have completed the project that you are thinking about. It is a relativlely easy conversion, if your were to do it yourself you would need a drill press, a machanist vice would really be nice, a collection of two-three drill bits and a 10/32 tap, with the necessary hardware to turn the tap.

Other than that if you have a machine shop in town or the vicinity they can complete the project in a few minutes time.

I would suggest a couple of things, I beleive the Lehigh vent liner to be the best of the vent liners offered, and when you drill the iniatial opening to fit the plug in make the opening 1/16th larger than the diameter of the diameter of the vent liner flange. If you look at my example you can see I made the same size as the vent liner. Later attempts were made larger. The larger cavity helps reduce blow back.

Last resort send it out here and I'll get it done for you...

Both Lee and I have completed the project that you are thinking about. It is a relativlely easy conversion, if your were to do it yourself you would need a drill press, a machanist vice would really be nice, a collection of two-three drill bits and a 10/32 tap, with the necessary hardware to turn the tap.

Other than that if you have a machine shop in town or the vicinity they can complete the project in a few minutes time.

I would suggest a couple of things, I beleive the Lehigh vent liner to be the best of the vent liners offered, and when you drill the iniatial opening to fit the plug in make the opening 1/16th larger than the diameter of the diameter of the vent liner flange. If you look at my example you can see I made the same size as the vent liner. Later attempts were made larger. The larger cavity helps reduce blow back.

Last resort send it out here and I'll get it done for you...

#8

Spike

Join Date: Nov 2009

Location: Rome, Ohio

Posts: 1

Sabotloader and Lemoyne, can you tell me what the angle was on the drill you used to open up the chamber side of the breech plug? I used a 90 degree spot drill and after checking where the vent liner touches the breech plug using dye it only touches near the threads at the base. The majority of the angled portion of the vent liner doesn't touch at all. Have you checked yours? Thanks.

#10

Nontypical Buck

Thread Starter

Join Date: Jan 2008

Location:

Posts: 1,408

So 10-32 is the thread size, right? What was the diameter (or is the 10 the diameter, I haven't used a tap set in a decade!).

My dad has a lathe and drill press next time I get up there but that'll be a few months so I want to make sure I have everything for the project when I go.