Conundrum!

#1

Yesterday I cast several hundred bullets and round ball for my muzzleloaders and they came out beautiful. Nice and shiny. My Lead thermometer was showing 725*. Any lower than that and the lead wouldn't pour from my bottom pour pot.

Today, after remelting the pure lead and emptying the pot into ingots I added my 13 BHN alloy ingots. After the ingots were melted and the temp stabilized at the same 725* +/- 10* and the mold properly warmed up I began casting. My bullets were coming out with a slight frosted appearance which generally means the alloy is too hot. But cooling even only down to 700* clogged up the pour spout. I do have a ladle to hand pour but I did not bring it with me to FL.

I don't really believe the frosted appearance will affect the bullets any. The spues are cut clean and the bottoms are nice and flat and the lube grooves are sharp. Other than being slightly frosted they are perfect.

Today, after remelting the pure lead and emptying the pot into ingots I added my 13 BHN alloy ingots. After the ingots were melted and the temp stabilized at the same 725* +/- 10* and the mold properly warmed up I began casting. My bullets were coming out with a slight frosted appearance which generally means the alloy is too hot. But cooling even only down to 700* clogged up the pour spout. I do have a ladle to hand pour but I did not bring it with me to FL.

I don't really believe the frosted appearance will affect the bullets any. The spues are cut clean and the bottoms are nice and flat and the lube grooves are sharp. Other than being slightly frosted they are perfect.

#2

Super Moderator

Join Date: Dec 2017

Location: texas

Posts: 1,201

the mild frosted appearance has ZERO negative effect on performance and in fact its tends to indicate a more consistent mold fill

the alloy change allowed the tin and antimony crystallizes content to more effectively fill the voids but results in a slightly more frosted appearance

heavy frosting generally tends to result in a slightly under sized bullet, shiney, has no benefit, other than aesthetics,

want to prove it?

get your best looking ten of each shiney and mildly or even completely frosted bullets , load each group exactly the same, now shoot both in separated groups

chances are very good little difference or the frosted group is marginally tighter,

set the first shiney bullets you cast aside and then weigh and measure them for comparison to the frosted ones.

740F-760F is generally fine, obviously cast at a rate that does not over heat the mold, if you get finning your generally casting too fast or theres debris in the mold

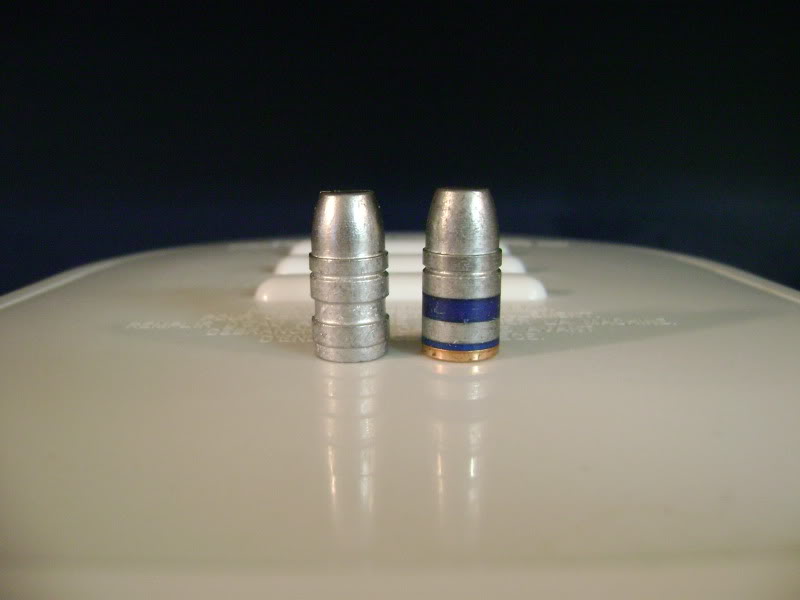

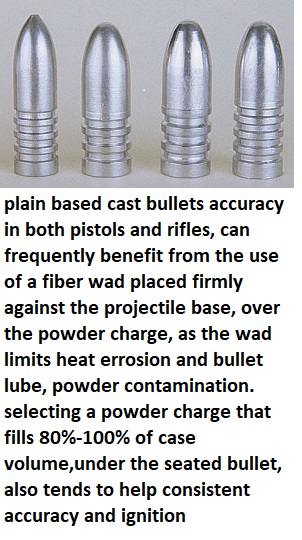

heres a picture I found someplace of mildly frosted and perfectly cast bullets

btw if your going to cast bullets wait till the molds clean and hot then lightly spray the mold interior surface with moly spray, as it helps the cast bullets fall easily from the mold and makes casting process faster and more consistent. (yes the first couple will suck, but after a couple fills the micro moly on the mold surface helps noticeably)

btw if your going to cast bullets wait till the molds clean and hot then lightly spray the mold interior surface with moly spray, as it helps the cast bullets fall easily from the mold and makes casting process faster and more consistent. (yes the first couple will suck, but after a couple fills the micro moly on the mold surface helps noticeably)

the alloy change allowed the tin and antimony crystallizes content to more effectively fill the voids but results in a slightly more frosted appearance

heavy frosting generally tends to result in a slightly under sized bullet, shiney, has no benefit, other than aesthetics,

want to prove it?

get your best looking ten of each shiney and mildly or even completely frosted bullets , load each group exactly the same, now shoot both in separated groups

chances are very good little difference or the frosted group is marginally tighter,

set the first shiney bullets you cast aside and then weigh and measure them for comparison to the frosted ones.

740F-760F is generally fine, obviously cast at a rate that does not over heat the mold, if you get finning your generally casting too fast or theres debris in the mold

heres a picture I found someplace of mildly frosted and perfectly cast bullets

btw if your going to cast bullets wait till the molds clean and hot then lightly spray the mold interior surface with moly spray, as it helps the cast bullets fall easily from the mold and makes casting process faster and more consistent. (yes the first couple will suck, but after a couple fills the micro moly on the mold surface helps noticeably)

btw if your going to cast bullets wait till the molds clean and hot then lightly spray the mold interior surface with moly spray, as it helps the cast bullets fall easily from the mold and makes casting process faster and more consistent. (yes the first couple will suck, but after a couple fills the micro moly on the mold surface helps noticeably)

Last edited by hardcastonly; 04-26-2019 at 05:22 AM.

#3

Hardcast the frosted bullets in your pic look exactly like mine. As for the moly on the mold that might be a good tip for later if my bullets stick to the mold. But normally they either fall out when I open the mold or do after a slight tap on the pivot bolt.. Thanks for your helpful tips.

#5

I watched a couple videos on lubing bullets and learned a couple things I didn't know. One that I didn't pay attention to was excess lube on the base of the bullet. Apparently this can reduce accuracy. I would have though that that lube would have melted off during firing. Is this true or a fallacy.

#6

Super Moderator

Join Date: Dec 2017

Location: texas

Posts: 1,201

have you ever wondered why cheap cast reloads have poor accuracy and smoke so badly?

non-gas check bullets that are faster to make and cheaper too use,

are generally used and lube mixed with the powder is a common contributing factor.

the answer to how to improve the accuracy and reduce the smoke?

depends on both the lube and the amount of lube, and Ive investigated this rather extensively,

its my observation that some lube melts and contaminates/degrades the powder charge,

lube contaminated powder does not burn well, and because you have very little control,

on the amount of lube reaching the powder in weeks or months of storage

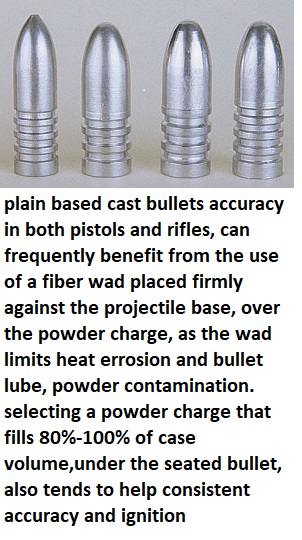

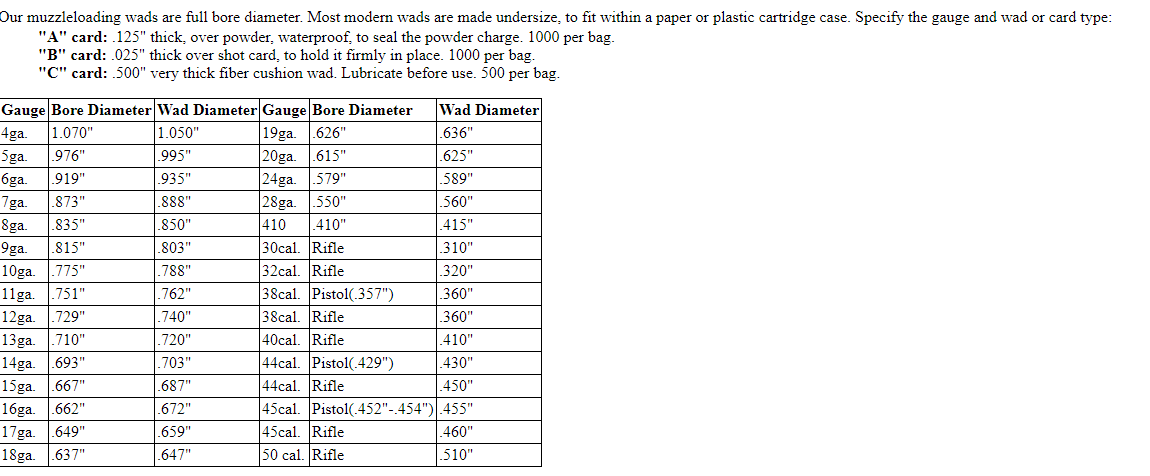

the cure is a properly installed barrier between the bullet and powder, an insert isolation wad

in the past bigger old school gun shops carried 357-44,45 caliber wads rather commonly

example on my 44 mag with non-gas check bullets

430" diameter Vegetable Fiber Wad, ideal for .44-40 caliber, .062" thick card, 1000, by Circle Fly Wads

if your loading non-gas check projectiles , especially with soft lube that may melt over time

,if left in a hot car or un-air-conditioned storage

load the powder charge, insert a spacer wad, then load and crimp the bullet,

remember the wad takes up powder space, thus it potentially raises pressure,at least marginally,

so you need to work up loads starting with about a 10% reduced load.

if this sounds like a P.I.T.A. your correct , most guys don,t shoot well enough to see a difference,

or at long enough ranges to see a difference and if you want to avoid the whole deal,

swapping to GAS CHECK BULLETS and harder lubes tends to eliminate the potential problem

the fiber wad you use should be pushed into the brass case as you seat the bullet,

and placed in solid contact with the base of the bullet,

there should be zero air space between the bullet base and the fiber wad

the wad acts like a fiber gas check thats not attached to the bullet base,

wads should be a tight fit in the brass case ,and in contact with the bullet base

in an ideal world you select a propellant powder charge that fills 85%-100% of the available space in the cartridge,

with the bullet fully seated and crimped in place, and provides you as close to the intended velocity at safe and consistent pressure,

as this generally provides decent accuracy and near peak design velocity

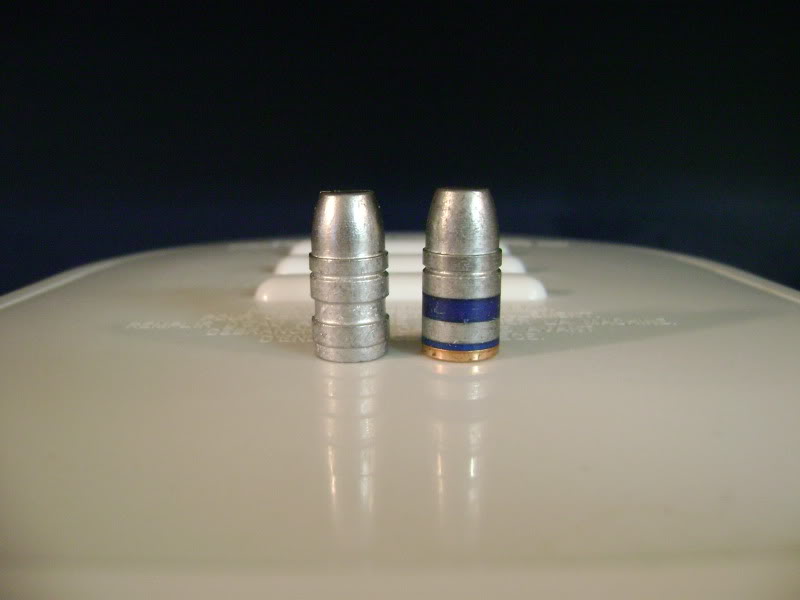

leaving any air space between the bullet base,and wad like the pictures below, is a BIG POTENTIAL PROBLEM

https://www.trackofthewolf.com/Searc.../2?search=wads

hardly new info

https://csharpsarms.com/cartridge%20...g%20manual.pdf

over card wads have been used since the 1860s to increase accuracy on cast bullet loads

read the sharps manual

non-gas check bullets that are faster to make and cheaper too use,

are generally used and lube mixed with the powder is a common contributing factor.

the answer to how to improve the accuracy and reduce the smoke?

depends on both the lube and the amount of lube, and Ive investigated this rather extensively,

its my observation that some lube melts and contaminates/degrades the powder charge,

lube contaminated powder does not burn well, and because you have very little control,

on the amount of lube reaching the powder in weeks or months of storage

the cure is a properly installed barrier between the bullet and powder, an insert isolation wad

in the past bigger old school gun shops carried 357-44,45 caliber wads rather commonly

example on my 44 mag with non-gas check bullets

430" diameter Vegetable Fiber Wad, ideal for .44-40 caliber, .062" thick card, 1000, by Circle Fly Wads

if your loading non-gas check projectiles , especially with soft lube that may melt over time

,if left in a hot car or un-air-conditioned storage

load the powder charge, insert a spacer wad, then load and crimp the bullet,

remember the wad takes up powder space, thus it potentially raises pressure,at least marginally,

so you need to work up loads starting with about a 10% reduced load.

if this sounds like a P.I.T.A. your correct , most guys don,t shoot well enough to see a difference,

or at long enough ranges to see a difference and if you want to avoid the whole deal,

swapping to GAS CHECK BULLETS and harder lubes tends to eliminate the potential problem

the fiber wad you use should be pushed into the brass case as you seat the bullet,

and placed in solid contact with the base of the bullet,

there should be zero air space between the bullet base and the fiber wad

the wad acts like a fiber gas check thats not attached to the bullet base,

wads should be a tight fit in the brass case ,and in contact with the bullet base

in an ideal world you select a propellant powder charge that fills 85%-100% of the available space in the cartridge,

with the bullet fully seated and crimped in place, and provides you as close to the intended velocity at safe and consistent pressure,

as this generally provides decent accuracy and near peak design velocity

leaving any air space between the bullet base,and wad like the pictures below, is a BIG POTENTIAL PROBLEM

https://www.trackofthewolf.com/Searc.../2?search=wads

hardly new info

https://csharpsarms.com/cartridge%20...g%20manual.pdf

over card wads have been used since the 1860s to increase accuracy on cast bullet loads

read the sharps manual

Last edited by hardcastonly; 05-02-2019 at 05:07 AM.