Breech plug question

#11

Boone & Crockett

Join Date: Apr 2007

Location: River Ridge, LA (Suburb of New Orleans)

Posts: 10,917

Well I understand Blackhorn users can omit using tape or anti-seize without a problem. But I'm a GOEX user and wouldn't even consider going with bare threads on the plug. Made that mistake once. Never again.

Now as to your question of "what torque is applied to keep the plug sealed..... assuming you have a good plug/barrel and not using tape or other sealers?" I just don't know. But on my two in-lines (Omega X7 and Lyman Mustang), I suspect it would take a LOT of torque to seal a bare plug. So much so that I wouldn't even want to try.

Now as to your question of "what torque is applied to keep the plug sealed..... assuming you have a good plug/barrel and not using tape or other sealers?" I just don't know. But on my two in-lines (Omega X7 and Lyman Mustang), I suspect it would take a LOT of torque to seal a bare plug. So much so that I wouldn't even want to try.

#12

Take into consideration the Remington Ultimate.....

Remington torques their breech plug to 80 inch lbs. Which is 6.6lbs. Now we know, or should know, that the RU is capable of extremely heavy charges, charges that all other production muzzleloaders are not capable of.

We know that some of the new rifles with finger tightening breech plugs, certainly don't use the same BP torque as the RU.

So would it be even close to say.......... 80ip is probably the maximum torque needed for any breech plug? If that can be agreed to, then the next question would be, what would be the minimum torque?

Remington torques their breech plug to 80 inch lbs. Which is 6.6lbs. Now we know, or should know, that the RU is capable of extremely heavy charges, charges that all other production muzzleloaders are not capable of.

We know that some of the new rifles with finger tightening breech plugs, certainly don't use the same BP torque as the RU.

So would it be even close to say.......... 80ip is probably the maximum torque needed for any breech plug? If that can be agreed to, then the next question would be, what would be the minimum torque?

#13

Boone & Crockett

Join Date: Apr 2007

Location: River Ridge, LA (Suburb of New Orleans)

Posts: 10,917

80ip is probably the maximum torque needed for any breech plug? If that can be agreed to, then the next question would be, what would be the minimum torque?

I would expect greater torque would improve the seal of the face of the plug against it's seat in the barrel - thus, the less likelihood of blow-by. But, does that have anything to do with the amount of pressure the plug can withstand?

For example, torque would clearly be a factor when bolting a lawn mower's motor to the mower deck because torque assures the tension between the motor base and deck surface is great enough to prevent unwanted movement (i.e. side-to-side slippage of two surfaces being held together).

But that's not the case in a muzzleloader's breech plug where we're concerned only with shear of the threads. under straight line pressure.

So here's a question for the mechanical engineers. Is thread shear pressure tolerance governed simply by the number and depth of engaged threads without respect to whether the threads or torqued? Or does torque increase the shear strength of the threads?

EXAMPLE:

We drill and tap two holes of the same diameter and thread count in an overhead steel beam. One hole is one inch deep and one hole is two inches deep. If we thread eye bolts into both holes so that;

(1) the bolt in the one inch deep hole is threaded in as far as it will go and torqued against the bottom of the hole, and

(2) the bolt in the two inch deep hole is threaded in one inch deep - the same depth as the other bolt - yet is not torqued at all because the hole is two inches deep.

Can we hang an equal amount of weight from each eyebolt since they both have the same number of threads bearing the weight. Or will the bolt under torque bear more weight?

#15

Nontypical Buck

Join Date: Aug 2014

Location: gilbert az

Posts: 1,168

i am not a engineer but i use and torque a lot of hardware in my profession and i would think they both hold equal weight so long as same amount of threads are equal. the torque is to keep two parts together from vibration as one example.

#16

I found this:

"The relationship between tension and torque should be looked at cautiously, since it is very difficult to indicate the range of conditions expected to be experienced by a fastener. Torque is simply a measure of the twisting force required to spin the nut up along the threads of a bolt, whereas tension is the stretch or elongation of a bolt that provides the clamping force of a joint. Bolts are designed to stretch just a tiny bit, and this elongation is what clamps the joint together. Torque is a very indirect indication of tension, as many factors can affect this relationship, such as surface texture, rust, oil, debris, thread series and material type just to name a few."

"The relationship between tension and torque should be looked at cautiously, since it is very difficult to indicate the range of conditions expected to be experienced by a fastener. Torque is simply a measure of the twisting force required to spin the nut up along the threads of a bolt, whereas tension is the stretch or elongation of a bolt that provides the clamping force of a joint. Bolts are designed to stretch just a tiny bit, and this elongation is what clamps the joint together. Torque is a very indirect indication of tension, as many factors can affect this relationship, such as surface texture, rust, oil, debris, thread series and material type just to name a few."

#17

This question DOES NOT include any finger tightening or QR style breech plugs.

For those who use a tool to tighten your breech plugs, has anyone actually verified the torque you apply seating it?

Don't need a single comparison concerning breech plugs or other comments.

Looking for someone who may have actually checked the torque (inch pounds) that they actually used.

For those who use a tool to tighten your breech plugs, has anyone actually verified the torque you apply seating it?

Don't need a single comparison concerning breech plugs or other comments.

Looking for someone who may have actually checked the torque (inch pounds) that they actually used.

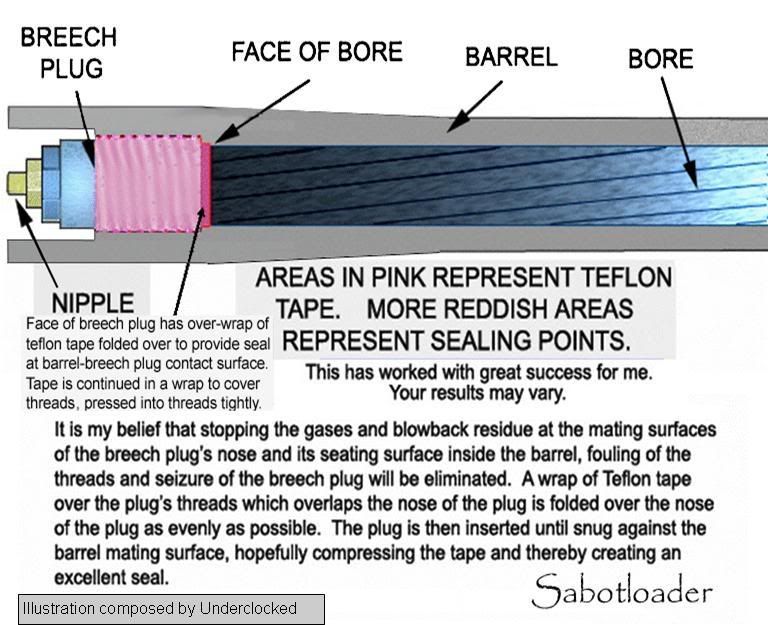

This illustration completed by Underclocked attempts to show what I am trying to say.

I do use Teflon tape to help maintain the seal. I have never liked grease.

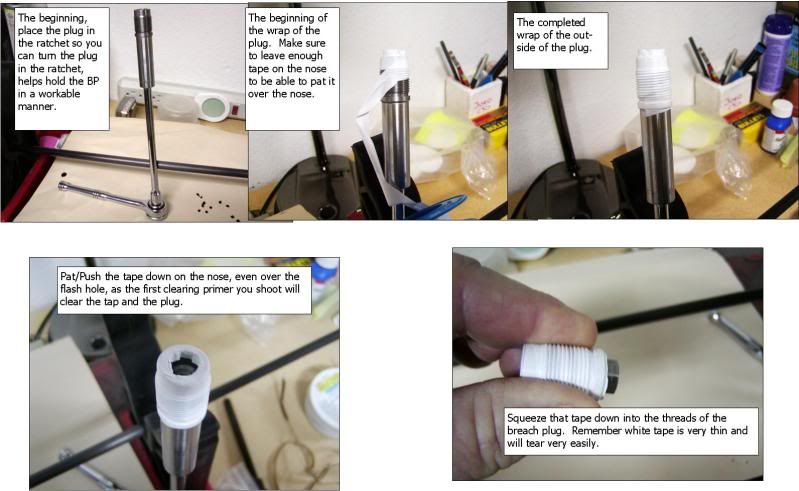

So I tape the plug as indicated in these pictures...

Then I install the plug in the rifle until it bottoms out. Then with the ratchet I apply and addition amount of pressure to squeeze the tape that has been placed over the nose to the shelf in the barrel. How many pounds I do not know but it is somewhat tight.

If I did my job correctly everything works as planned noting on the threads and the plug comes out with the ratchet again...

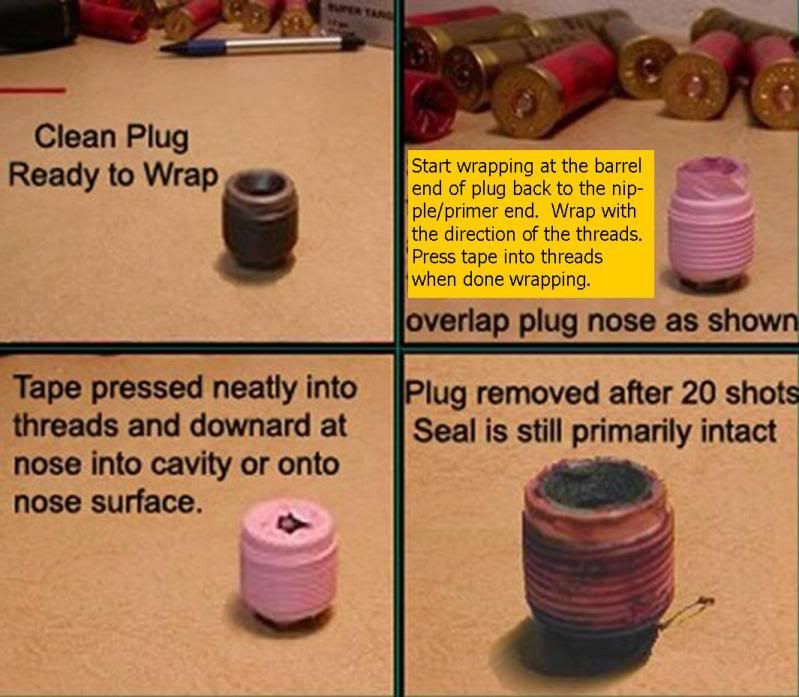

This set of pictures is a Remington plug wrapped in pink tape shot several times and removed. I should tell most often the white does not come out on the BP but stays in the threads of the barrel. A simple bronze brush rotated CCW bring the remains out.

So in all of this I can tell you the specific torque - it is feel I have developed over a lot of years. The plug is SNUG!

Last edited by sabotloader; 01-27-2016 at 06:34 PM.

#18

In all honesty - I can not tell you the amount of torgue that I use for the breech plug. For many years I tried different methds including backing off a bit or tightening just until the plug bottomed. Several years ago I changed my thoughts on this. It is my reasoning that the breech plug - barrel gas seal should occur when the nose of the breech plug meets the shelf in the barrel. If the nose is seal is formed there then the blow back gases will be stopped at that point. Threads will not be fouled and gas cutting of the threads will not occur. I shoot T7 so I need to be vigelent about this because at a range session I never loosen the plug.

Is there any way and do you have the equipment to do a test with one of your rifles?

#19

Nontypical Buck

Join Date: Aug 2014

Location: gilbert az

Posts: 1,168

i'm not sure you would consider a white nipple a breech plug i would anyway i have been installing by hand with the bp tool then back off just a tad but never seen any evidence of blow back on the threads i would think with enough threads and some type of grease there wouldn't be any gases getting thru ? any thoughts ?

#20